The Industry Is Changing. So Is the Way Pros Connect.

In the past, connecting HVAC/R systems meant hauling around torches, applying for hot work permits, scheduling fire spotters, and following time-consuming procedures. But the industry is evolving. Tighter project timelines, stricter safety codes, and the increasing use of flammable refrigerants are pushing professionals to find faster, safer solutions. That’s why more HVAC/R technicians and contractors are making the switch to press fittings.

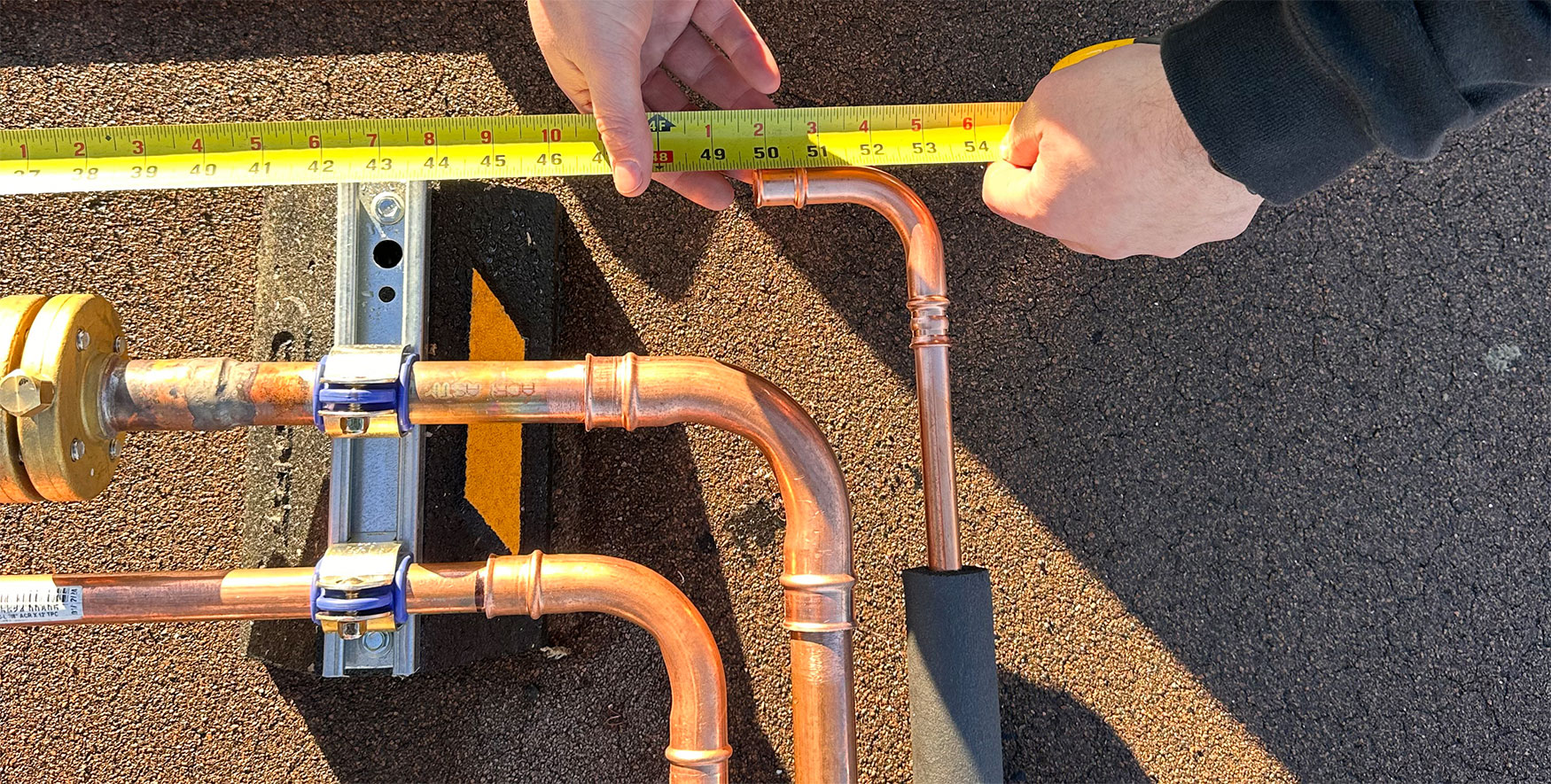

Press-to-connect technology offers a reliable, flame-free alternative to brazing. Using a press tool and specially designed fittings, technicians can create permanent, leak-free connections in just seconds—no torch, no nitrogen, no fire watch. Just press and go.

Flame-Free Safety

Flame-Free Safety

Removing the flame removes the risk. Press fittings eliminate the need for hot work permits, nitrogen purging, fire spotters, and the transport of gas tanks—significantly reducing jobsite hazards. This is especially important as A2L refrigerants become more common in both new construction and retrofits.

In sensitive environments like hospitals, schools, and clean rooms, brazing is often prohibited or discouraged. Press technology enables clean, sealed connections without the safety concerns associated with open flame.

Faster Installs, Speed That Pays Off

Faster Installs, Speed That Pays Off

Pressing a fitting takes about 10 seconds. That speed adds up quickly, allowing contractors to complete projects up to 60% faster than traditional brazing methods. With no setup, no cooldown, and no fire watch required, crews can move efficiently from one connection to the next.

The simplicity of the press process also makes it easier for newer technicians to learn, enabling teams to grow without sacrificing job quality or slowing down.

Reliable, Repeatable Results

Reliable, Repeatable Results

Unlike brazing, which depends heavily on individual technique and experience, press fittings deliver a consistent connection every time. This repeatability reduces the chance of installation error, minimizing the risk of leaks and system failures.

For contractors, that means fewer callbacks, fewer warranty claims, and more confidence that every connection will hold up under pressure.

Better Access in Tight Spaces

Better Access in Tight Spaces

Press tools are built for performance in spaces where brazing would be difficult, dangerous, or impossible. Whether you’re working in a mechanical closet, overhead space, or near flammable materials, press technology makes it possible to complete connections without moving equipment or evacuating nearby systems.

This flexibility is especially valuable in retrofits or jobs with tight access requirements, where traditional flame-based methods would require additional prep or shutdowns.

Cut Total Installed Costs

Cut Total Installed Costs

Press fittings don’t just save time—they also help reduce total installed costs. By eliminating the need for flame-related equipment and reducing labor hours, press technology streamlines your workflow and lowers operational expenses.

Because each press is consistent and fast, you also spend less time on rework and cleanup. The end result is a more efficient install, from start to finish.

The Industry’s Most Trusted Press Fittings

The Industry’s Most Trusted Press Fittings

RLS pioneered press-to-connect fittings specifically engineered for HVAC and refrigeration systems. With millions installed globally and third-party certification to UL 207 and ISO 14903 standards, RLS fittings are trusted by professionals who demand performance and durability.

Every fitting is designed for pressure up to 700 psi, and field-tested for long-term reliability. When you choose RLS, you’re choosing proven performance backed by years of real-world results.

Ready to Ditch the Flame and Move Faster?

RLS press fittings help contractors work safer, faster, and smarter—without compromise. Make the switch and see how press-to-connect can improve your process, your productivity, and your peace of mind.

In the past, connecting HVAC/R systems meant hauling around torches, applying for hot work permits, scheduling fire spotters, and following time-consuming procedures. But the industry is evolving. Tighter project timelines, stricter safety codes, and the increasing use of flammable refrigerants are pushing professionals to find faster, safer solutions. That’s why more HVAC/R technicians and contractors are making the switch to press fittings.

Press-to-connect technology offers a reliable, flame-free alternative to brazing. Using a press tool and specially designed fittings, technicians can create permanent, leak-proof connections in just seconds. No torch, no nitrogen, no fire watch. Just press and go.